Microbial Fuel Cell process

Microbial Fuel Cell

Introduction

Base on the global statistics, energy consumption growing rate 2018-2019 was equal 2.9% which is almost double the 1.5% from 2010 to 2018. Actually, among energy resources, fossel fuels are still the dominant resource of energy production and they are accounted for 85% share of energy production in the world(2017)(Microbial Fuel Cell)

. Renewable energy production (from wind, solar, and biofuels), grew at the rate of 7.43% by year from 2008-2018

. Production energy from biofuels also grew 6.15%

by year at the same period. It is unequal share of fossil fuels and renewable energy production led to emission a huge amount of greenhouse gases into the world atmospher

. Therefore, due to some real issues such as global warming and increasing the level of greenhouse gases in atmosphere, it is urgent to consider another energy resource and increase the share of renewable resources, which are green and environmental friendly.

Among new technologies fuel cells(Biofuels) have some advantages in realm of energy generation (however, there are some obstacles which can restrict the speed of spreading this technology ).Fuel cells are electrochemical devices to convert chemical energy into electrical energy, high have a higher electrical efficiency (≥40 %) compared to conventional power generation systems

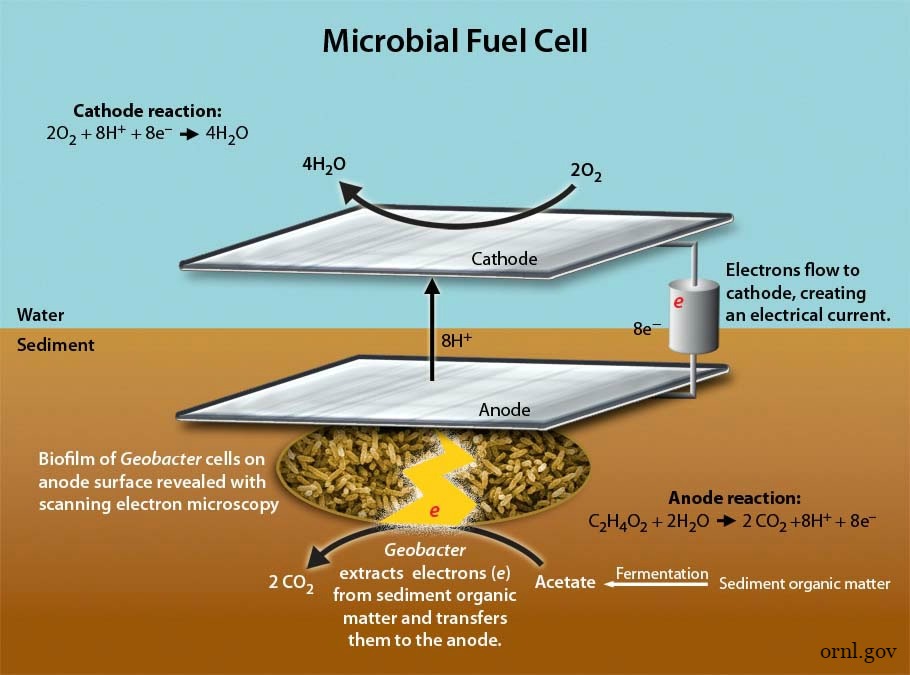

. A microbial fuel cell (MFC) is a hybrid bio-electrochemical device that converts the energy stored in chemical bonds in organic compounds to electrical energy through catalytic reactions that occur in microorganisms

. A microbial fuel cell utilizes microbial redox reactions to produce electricity , due to the fact that, MFC uses waste organic material to produce electricity and this process is nonpolluting, MFC is highly sustainable energy producing method Microbial fuel cells are a type of fuel cell utilizing microorganisms to produce electricity from organic wastes

Microorganisms, such as bacteria, can generate electricity by utilising organic matter and biodegradable substrates such as municipal wastewater Microbial fuel cell (MFC) technology offers numerous opportunities for wastewater treatment

.Pollutant degradation efficiency and the maximum power density generation are the benefits of MFCs

Applications of Microbial fuel cell (MFC)

In Comparison with conventional aeration technologies for wastewater treatment, MFCs produce less sludge with net energy production. MFCs are vastly examined in wastewater treatment, greenhouse gas recognizing and mitigating, biosensing, polluted sediment ,and finally surface water remediation. Some problems on the way of using MFCs can be considered like, costly electrode material, huge capital cost and inadequate electricity conversion efficiency restricted its large-scale application

Power generation

MFCs utilise the bio-catalytic capabilities of viable microorganisms and are capable of using a range of organic fuel sources, by converting the energy stored in the chemical bonds, to generate an electrical current instead of relying for example, on the use of metal catalysts

. Microorganisms, such as bacteria, can generate electricity by utilising organic matter and biodegradable substrates such as wastewater, whilst also accomplishing biodegradation/treatment of biodegradable products, such as municipal wastewater.

had been reported that the bioelectric energy efficiency in MFCs is highly dependent on the source and substances of organic matters. Also, it depends on the electron transfer efficiency from anode to cathode.

Illustration: Anaerobic Anodes form the surface upon which fuel oxidation takes place with the cell, as such, correct design and materials selection are vital for high performance and long term durability . The aerobic cathode side of all fuel cells is fed with oxygen ].

Biosensor

It’s vital to monitor and detect the toxic compounds and other contaminants for some industries and applications in the field of environmental and clinical production. Therefore, due to the availability and accessibility to biomaterials, using them in the realm of detecting contaminants have been widely recommended

. Biosensors are analytical devices used to detect specific analytes. They are analytical devices that convert a biological response into a quantifiable and processable signal

. They have umerous existing and prospective applications in various domains

. The biological sensing element can be enzymes, antibodies, cell receptors and DNA probes, which interact with a specific analyte.

The transducer can be a piezoelectric, optical or physicochemical material, that translates the biological signals to electrical and optical signals. Biosensors can be divided into different categories: (1) amperometric biosensors (measure the electrical current); (2) potentiometric biosensors (measure electrical voltage); (3) conductometric biosensors (measure electrical conductance); (4) optical biosensors (measure the absorbed or emitted light) (5) calorimetric biosensors (measure the change of enthalpy) and (6) piezoelectric biosensors (detect stress) [19]. Microbial fuel cell (MFC) as a biological sensor, widely has been used to detect and monitor toxicity and environmental pollution on industrial applications and other environments, some cases has been presented in table 1.

Conclusion

Based on the scientific researches, which have been reviewed in this paper, it is clear that MFC technologies have the potential to play a major and basic role in transition to more renewable and green energy sources.

Actually, due to the fact that MFCs produce no hazardous waste in process of energy generation, they are highly trustworthy as a renewable energy resource.

Also, in other fields and areas, such as wastewater treatment and biosensors using MFCs was highly efficient and it is clear that they can be replaced with other regular and traditional methods and technologies.

However, due to the low level of power generation, highly expensive materials such as electrode which made it difficultl to scale up MFCs in realm of industrially usage, it is clear that there is an urgent need to optimizing and tailored development of individual parameters such as, enhanced electrode materials that are more suitable for this application.